Mirror your design before printing!

Overview

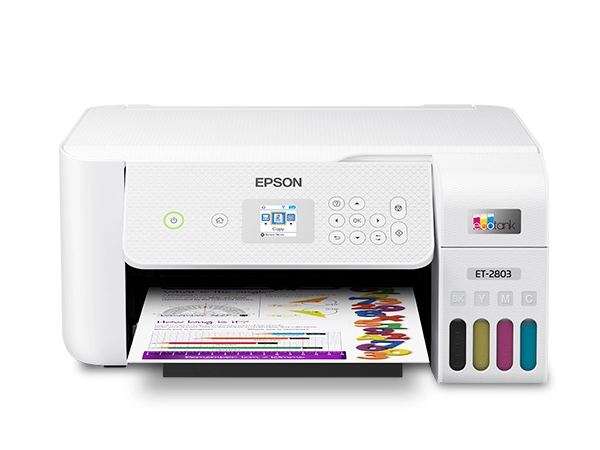

The Epson ET-2803 is a sublimation printer that has been modified to use sublimation ink. Sublimation printing involves the transfer of dye onto a substrate such as fabric or plastic using heat and pressure. This type of printing produces high-quality, long-lasting images with vibrant colors and is commonly used in the production of custom t-shirts, phone cases, and other products.

Risks

- Ink toxicity: Sublimation ink can be toxic if inhaled or ingested, so it's important to use proper ventilation and protective equipment while using the printer.

- Ink staining: Sublimation ink can stain clothing, skin, and other materials, so it's important to take precautions to avoid accidental spills.

Glossary

- Sublimation Ink: A special type of dye that turns into a gas when heated and bonds with polyester fibers or polymers to create a permanent image.

- Sublimation Printer: A printer that uses sublimation ink and heat to transfer images onto polyester fabrics, ceramics, or other polymers.

- Epson ET-2803: A modified Epson EcoTank printer that has been converted for use with sublimation ink.

- Polyester Fabric: A synthetic fabric that is commonly used for sublimation printing.

- Heat Press: A machine that is used to apply heat and pressure to transfer sublimation ink onto a substrate.

- Substrate: The surface or material that the sublimation ink is being transferred onto.

- Transfer Paper: A special type of paper that is used in conjunction with sublimation ink and heat to transfer the image onto a substrate.

Materials

The following materials are recommended for use with the Epson ET-2803 sublimation printer:

- Sublimation Ink: Only use Hiippo Sublimation Ink. Do NOT fill the sublimation printer with normal ink as it will not sublimate and will require substantial cleaning to reconvert the printer for sublimation. And mixing with other sublimation inks may affect color consistency.

- Sublimation Paper: Use a high-quality sublimation paper to ensure proper ink transfer and prevent smudging or bleeding. Regular paper will not transfer sublimation ink effectively.

- Substrates: Sublimation ink can be transferred onto a variety of substrates, including polyester fabrics, ceramic tiles, and metal products. It is important to choose a substrate that is compatible with the sublimation process and has a high polyester content to ensure proper ink transfer and color reproduction. Most notably, sublimation ink does NOT transfer to cotton. 50/50 cotton/polyester blends will result in a highly faded look.

Procedures

Printing a sublimation design

- Prepare the design to be printed. We recommend 300 DPI when sublimating on smooth surfaces, and 150-200 DPI for fabrics and textured surfaces.

- Mirror the design before printing, as sublimation ink is printed in reverse on the transfer paper.

- Load sublimation paper into the printer.

- From the print dialog in your application, select the Epson Sublimation Printer (ET-2800 series) and adjust the print settings as necessary. It is recommended to use the highest print quality setting to ensure a sharp and vibrant image.

- Print. Remember, the print should appear mirrorred!

- Once the print job is complete, remove the transfer paper from the printer and allow it to cool for several minutes.

- Now your design is ready for the heat transfer process. If using the heat press, see the Heat Press SOP for relevant procedures.

Refilling the sublimation ink

- Gather Hiipoo Submlimation Ink refill with the Autofill mouth. If the autofill bottles are empty, refill them from the non-autofill bottles. The autofill bottles greatly reduce leakage and cleaning.

- Make sure the printer is turned off and unplugged.

- Select "Fill Ink" from the Maintenance menu on the printer, and follow instructions.

- Using the Hiipoo Sublimation Ink bottle, attach the autofill mouth to the printer's ink tank for that color.

- Do NOT squeeze to bottle. Let gravity drain the ink for several seconds. The autofill bottle will stop draining once the printer's ink tank is full or the bottle is empty.

- Remove the autofill bottle.

- If any ink leaked or spilled, wipe it clean immediately.

- Turn the printer back on and perform a printhead cleaning to prime the ink system.

- You can now resume printing.

Please do NOT discard the autofill bottle even if it is empty. We refill the autofill bottles from larger non-autofill bottles.